New Design Weather-proof Type Transformer Oil Filter Machine 1800LPH

ApplicationREXON ZYD-30 transformer oil filter machine is a newly designed weather-proof type machie with flow rate 1800 litres/hour for transformer maintenance. The doors in two directions are divided into two parts, the upper part is a gas strut structure that opens upwards to effectively block the sun or rain, and the lower part of the door is open to the left and right, and can be opened or closed as needed. The doors in the other two directions are fully open to the left and right, and can be opened and closed according to the needs of the site. This design saves more space and is convenient to use.

REXON ZYD-30 oil filter machine mainly used for electric power departments and industries to deal with various oils such as transformer oil, mutual oil, switch oil, insulating oil, dielectric oil and so on. The machine is especially for purifying the insulation oil in all kinds of large power equipment that are above 110KV, especially for the altitudes is over 500-1000 meters. It can remove the free and dissolved water, gas, and particles from oil highly efficiently, increasing the pressure force and quality of oil, and making sure the electric device runs safely. The dielectric value of treated oil is higher than 75~85KV. It is very suitable for large electric & insulation equipment.

Features1. It has a two-stage high-speed vacuum system and a multi-stage vacuum analysis separation system, which can quickly remove moisture, gas, impurities, polar substances and other degraded substances from the oil.

2. The three-dimensional flash dehydration and degassing technology is adopted to efficiently remove water and gas from the oil, so that the breakdown voltage can be rapidly increased to more than 70KV.

3. The effect of one-time filtration is greatly improved, which reduces the risk of oil aging caused by repeated filtration and heating in general oil purifiers.

4. Using the independent dual-channel technology of complex oil and gas, the secondary re-dissolution technology in the separation of oil and gas can be used to quickly remove various organic hydrocarbon gases in the oil, ensuring that the content of acetylene and hydrogen in the oil is zero.

5. Heating by carbon fiber infrared heating system which is the most advanced heating technology, the unique heater structure heats the oil uniformly and easily controlled, it gives out the heat quickly (in 3 seconds after power on) and efficiency of electricity transforming to heat is very high (more than 98%). High efficiency, low density heating method for oil, which can prevent oil cracking at high temperature.

6. The use of multi-stage high β-value compound progressive filtration system can effectively filter the fine particles of mechanical impurities in the oil.

7. Online oil filtering, unattended operation, vacuum oiling of transformers, etc.

8. Advanced liquid level automatic control system, automatic defoaming control system, pressure protection system and safety interlock control ensure long-term, safe and reliable operation of the equipment.

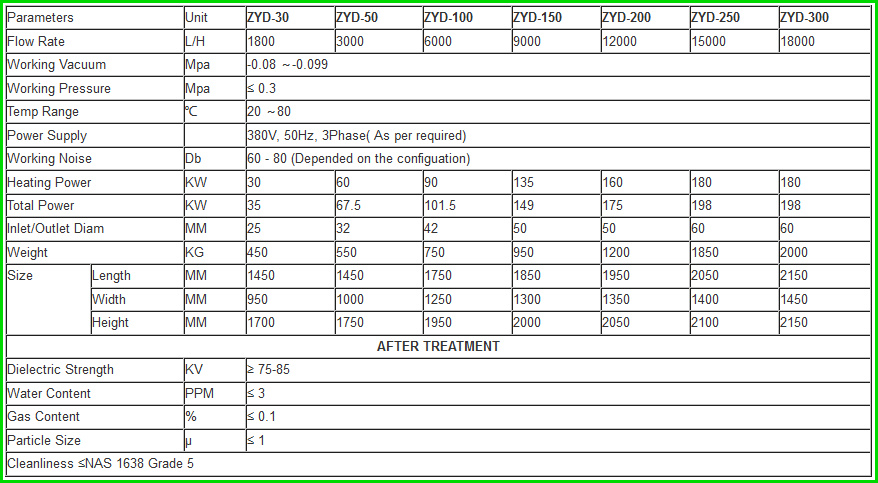

Technical Parameters