600L/H PLC Automatic Touch Screen Type Lube Oil Filtration Purifier

Preview

During the use of lubricating oil, foreign matter may be generated due to pressure, friction, environment, etc. These foreign substances act as catalysts to trigger oxidation of the oil to form free oil-insoluble matter, resulting in oil contamination. As the pollution increases, the viscosity and acidity change, the moisture increases, and the color of the oil changes, which in turn causes equipment failure, resulting in the replacement of oil. The residual polluted oil in the equipment circulation system is mixed with the new oil to play the role of oxidation catalysis, which will accelerate the pollution rate of the oil and reduce the use time of the new oil. Therefore, in order to prevent oil contamination and prolong the service life of the oil, it is necessary to quickly remove the pollutants and oxides formed in the oil.

Application

REXON series TYA vacuum Lubricating oil purifier machine is applied to recover and purify various high-precision lubricating oil such as hydraulic oil, mechanical oil, coolant oil, gear oil, heat treatment oil and so on. Our TYA oil purifier can rapidly remove water and moisture(free water, dissolved water and trace water), impurities, tiny particles, dust, metal sludge, etc from contaminated lube oil, so to clean oil and regenerate oil. After the purification process, the used oil can get new oil lie with qualified property to be used again as new oil.

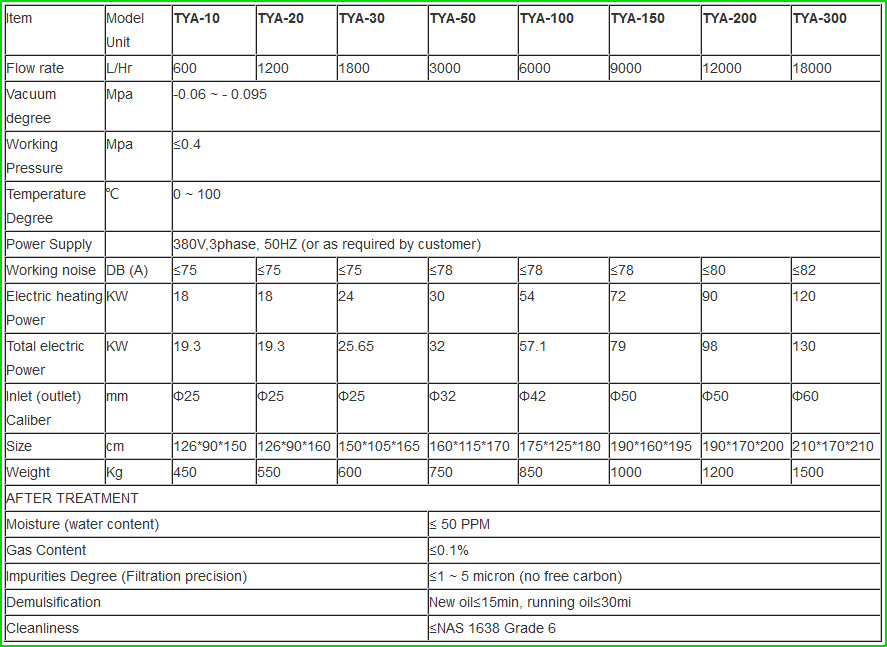

Technical Parameters

- Previous Product:Multi Functional Lubricating Oil Purifier Machine

- Next Product:Vacuum Used Lubricating Oil Regeneration and Recycling Machine